※Progressive Stamping : Progressive stamping is a metalworking method that encompasses plural processes such as blanking, bending and drawing combined with a sheet metal feeding system in one die.

Medical

Example of Application

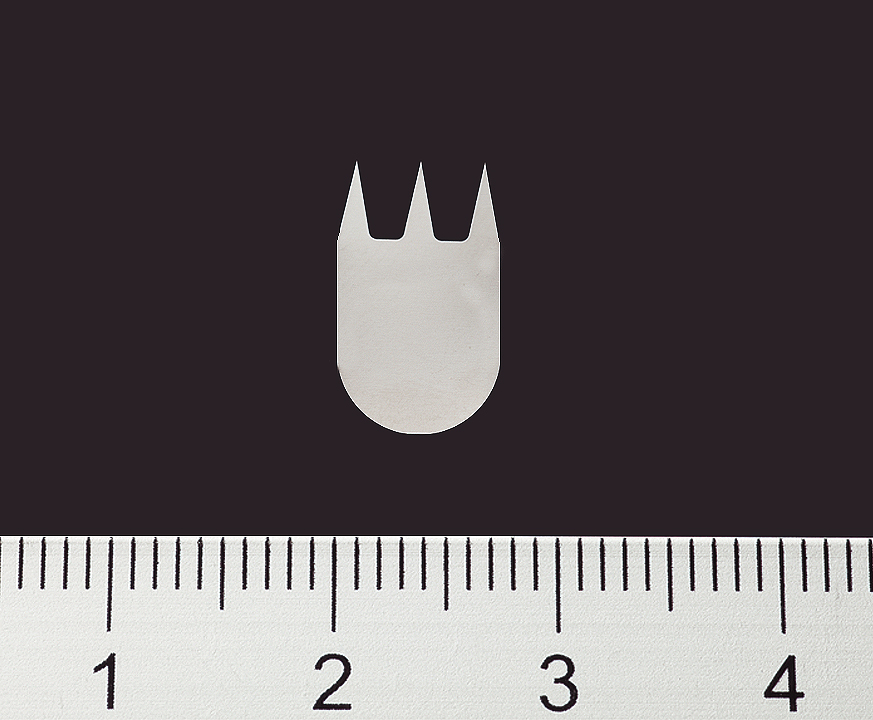

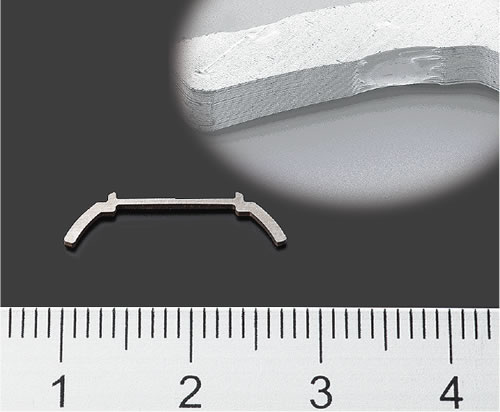

Sharp Points Medical Device Part

Feature of Part

This product used to be made by grinding one-by-one. So the product can be supplied at extremely expensive price. It is possible to lower the cost if it is made by lathe. But it could only make coincidently few pieces out of a thousand pieces.

JKB has developed truly groundbreaking technology of making this product by stamping and we achieved making a sharp edge of 6μm in all directions.

Therefore we are able to supply this product within 1/1000 of the past price.

We contribute a lot to the medical field to enrich peopleʼs health care through supplying our new product.

Example of Application

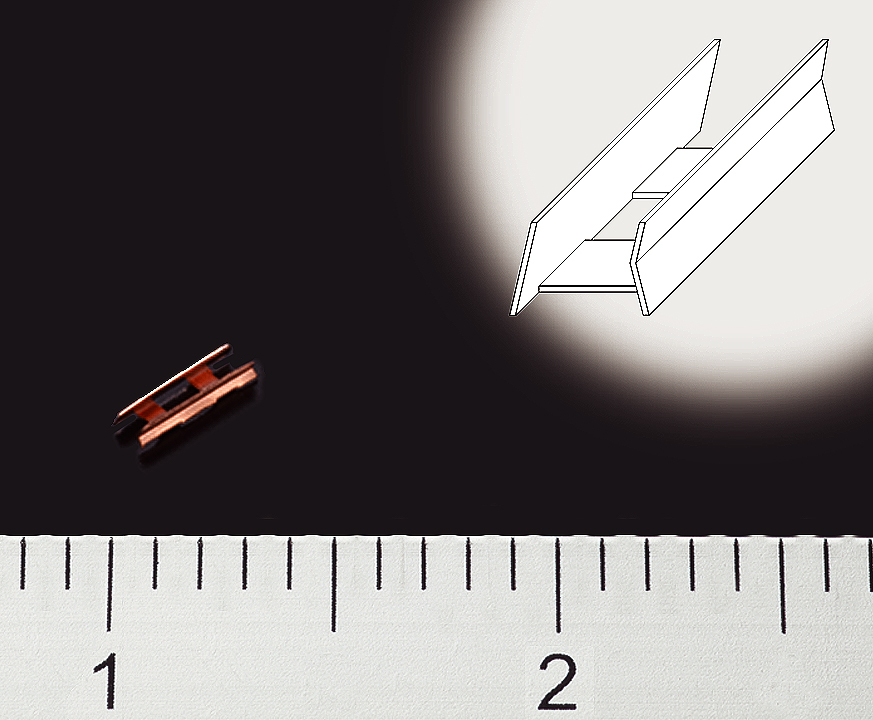

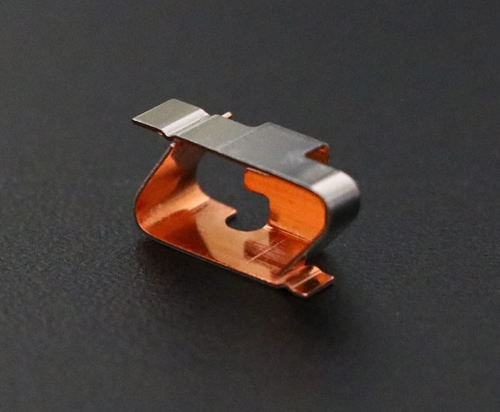

Medical Clip

Feature of Part

In the past, this product was extremely difficult to make since the stamping required a very high level of precision, as the material is only 0.06mm in thickness.

We successfully make this form at an accuracy of ±10μm using a progressive die. This process is exceptional taking into consideration the extreme thinness of the material being manipulated.

Example of Application

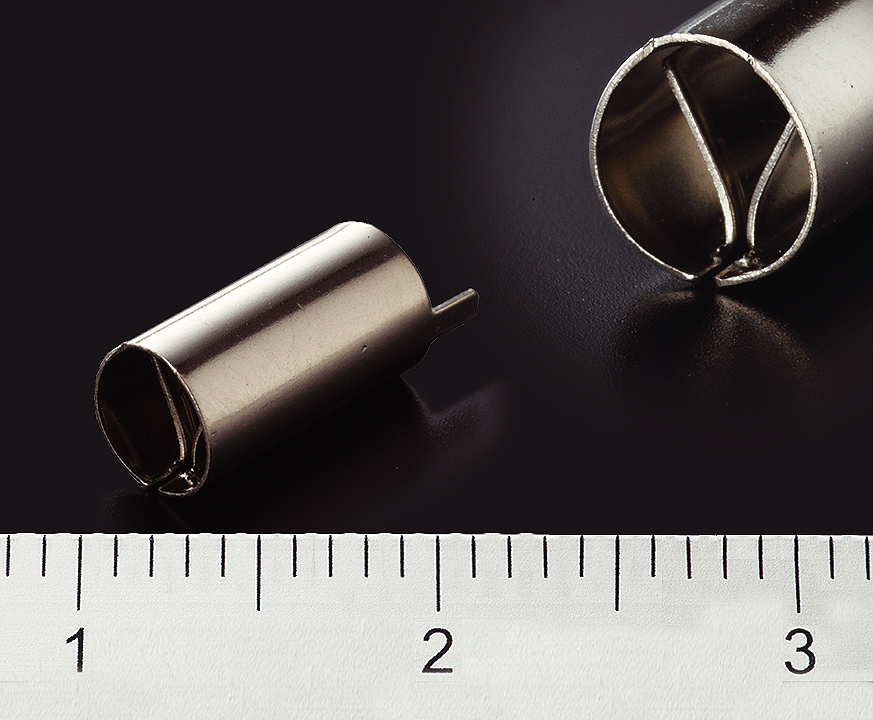

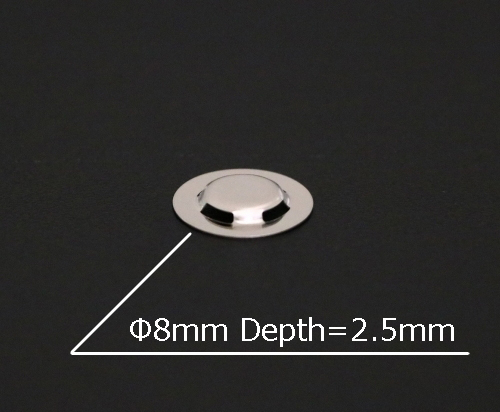

Medical Joint Part

Feature of Part

This product was previously difficult to make because the form has a V-shaped wing inside a circular shape which required a precise circularity. This product was made by combining two separate parts, one being circular in shape , the other having a Vshaped wing.

We are successful in making the entire shape in one strike using a progressive die. We also achieve a circularity of 20μm for the circular part of this product that includes a V-shaped wing.

Electronics

Example of Application

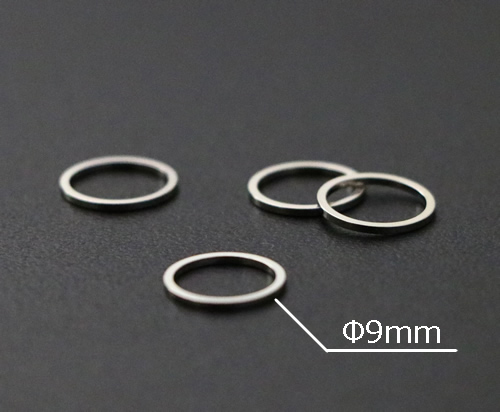

Diaphragm Ring

Feature of Part

When rings are made by stamping, warping often occurs. To achieve ultra-flat rings, polishing treatment is required, which results in additional costs.

JKB succeeded in stamping metal rings with a flatness of 10μm. As a result, the post-processing polishing treatment was reduced, which lowered costs.

Example of Application

Antenna Core

Feature of Part

JKB succeeded in manufacturing an ultra-high precision stamping die and realized continuous stamping of extremely hard materials. Additionally, productivity and quality were improved by laminating and fixing the plates using laser welding. Furthermore, JKB succeeded in laminating and fixing 20 stamped plates using ultra-precise laser welding without changing the metal's properties.

Example of Application

Cladding Metal Connector

Feature of Part

Stainless steel and copper cladding materials have different bending properties on the front and back surfaces, which causes distortion during bending, making high-precision processing and stamping difficult.

JKB excels at high-precision punching and bending of cladding material using progressive stamping dies.

Example of Application

Metal Cap

Feature of Part

JKB realized progressive stamping to succeed in drawing with high precision, ensuring the dimensional accuracy of the slit from the side to the bottom.

Example of Application

Metal Case

Feature of Part

It is usually necessary to use a 0.3mm welding projection from the edge which makes it difficult to stamp such products.

JKB achieved the production of a 0.3mm stamping die and can make such cases using progressive stamping dies.

R&D

Example of Application

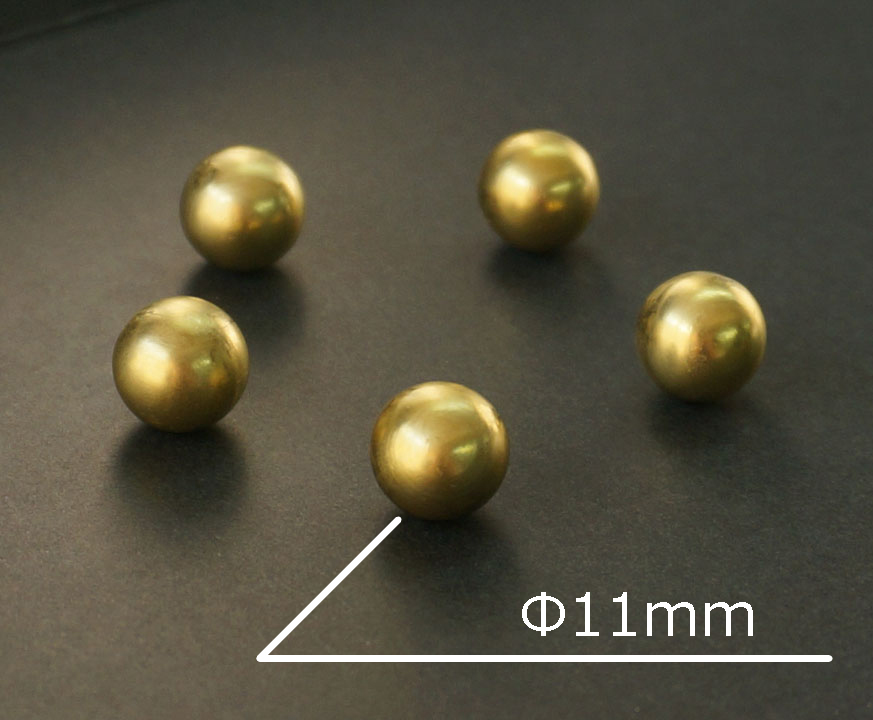

Spherical Body

Feature of Part

It was impossible to make a spherical object from a plate without having an opening area on the shape.

We are successful in stamping completely sealed spherical body from a flat plate.

Example of Application

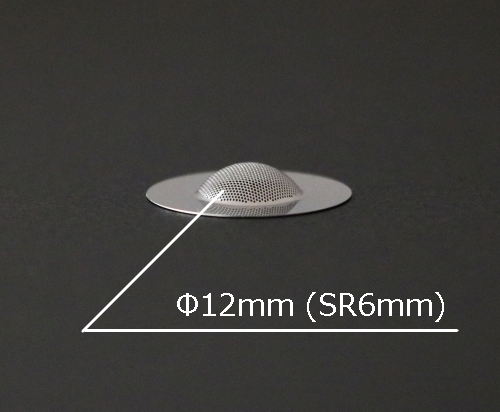

Domed Mesh

Feature of Part

Problems such as the mesh breaking and the hole shape deforming occur when the parts are stamped because of the fine mesh shape. Typically, solving these problems cannot be achieved without making changes such as increasing the plate thickness or making the mesh less fine.

JKB succeeded in stamping the above-mentioned part defect-free and not only achieved high precision but also realized the commercialization of such parts.

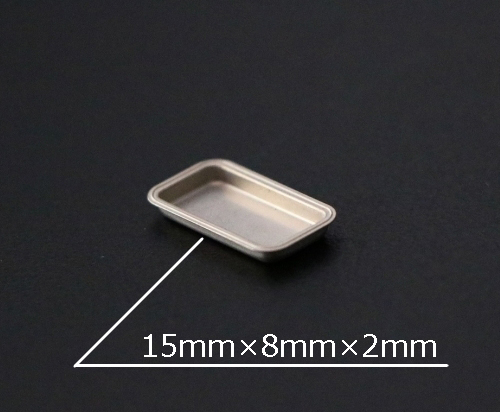

Example of Application

Micro Device

Feature of Part

By making the plate thinner than conventional products and successfully stamping it with a flatness of 10μm, JKB was able to minimize costs, contributing to the expansion of research and exploring the possibilities of such disposable parts.

These requirements came from Tokai University's Keishi Kimura Laboratory.

Industrial

Example of Application

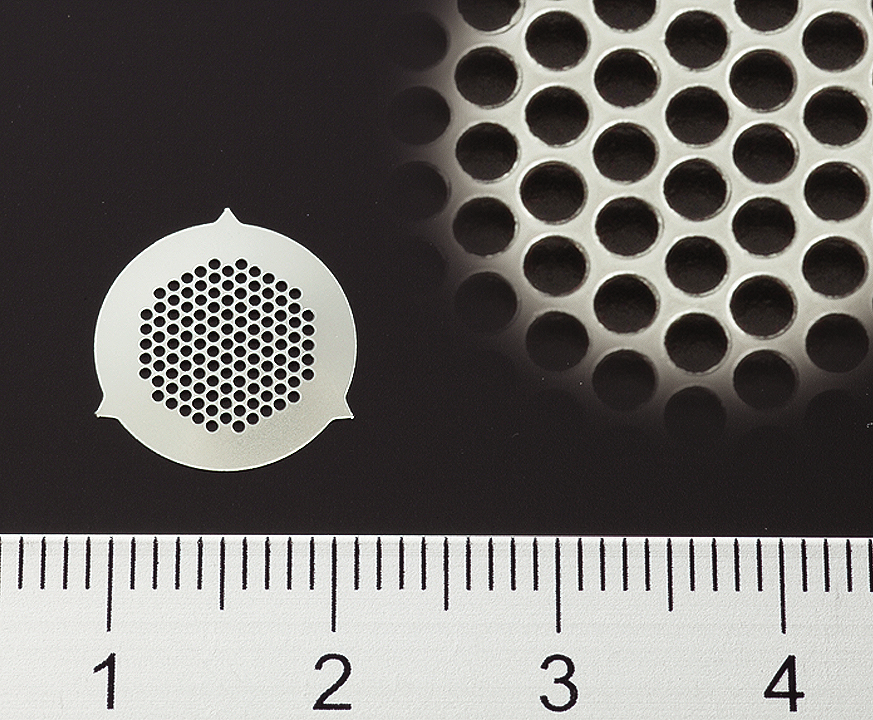

Filter

Feature of Part

This product was previously made using photo etching which required an ultra microscopic process. As a result , production costs were high.

We are successful in stamping more than 120 small holes within the area of 1/6th of a 10-cent coin. The tolerance of the hole pitch is less than 3micrometers. The price of this product is greatly reduced to 10% of the current market price.

Example of Application

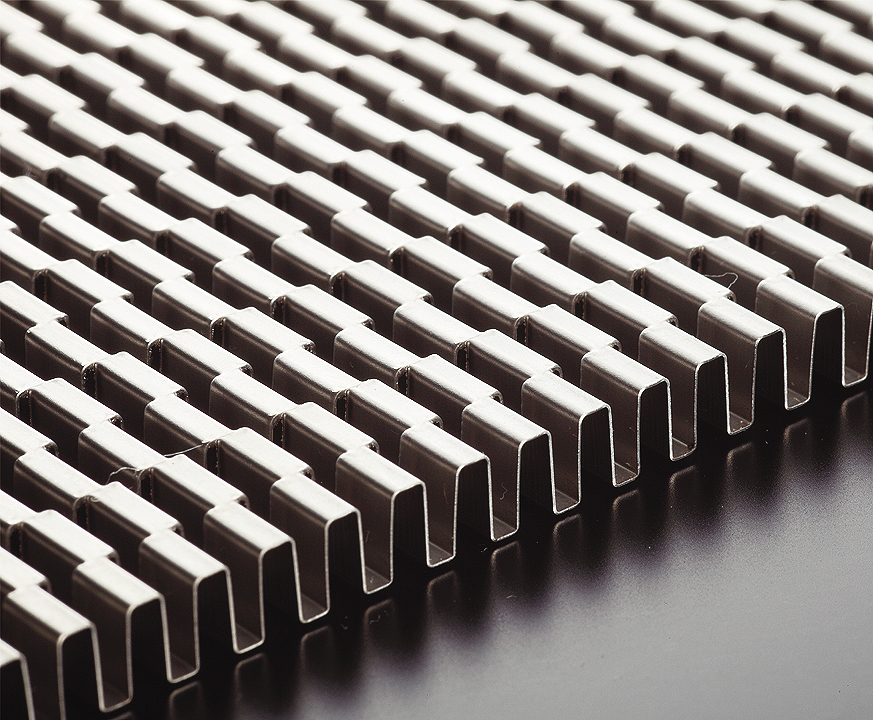

Offset Strip Fin

Feature of Part

To stamp this product using the current technology on the market is impossible without the separation of the metal into small pieces. Therefore, the processing conditions required are extremely complicated and highly complex.

JKB has been able to develop truly groundbreaking technology, utilizing a combination of lancing and drawing of stainless steel. We are successful in making this form using one progressive die. We are the first company in Japan to achieve this solution.

Example of Application

Plug, Connector

Feature of Part

It was difficult to make this product by a progressive die because it was hard to design a carrying web (a connecting part required in the shape for feeding the raw material). The processing of this form required several steps using a combination of different dies.

As a result, this product was supplied in small quantities and at a high price.

We are successful in stamping this product using one progressive die. This form is made by stamping out, bending and squeezing with one strike of the die. Therefore, we are able to supply this product in large quantities and at a significantly lower price.

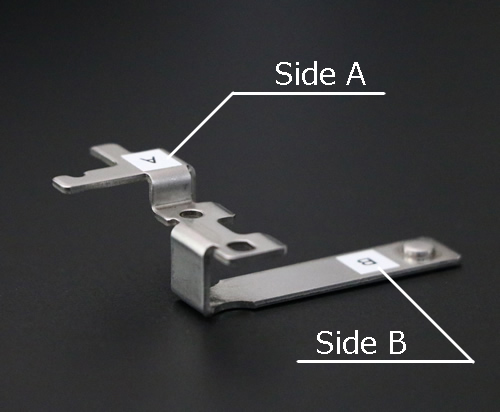

Example of Application

Mechanism Element

Feature of Part

It is necessary to make Side B so that the parallelism between Side A and Side B is 0.1mm or less, but the part that connects Side A and Side B must be bent four times, making it impossible to ensure parallelism accuracy.

JKB utilizes progressive stamping with a single bending accuracy of 0.02mm. As a result, we succeeded in achieving a high accuracy of parallelism of 0.1mm or less between Side A and Side B.